In recent years, as environmental protection policies have become more and more stringent, traditional enterprises represented by the textile and garment industry are speeding up the pace of transformation and development, and the concept of sustainable development runs through the entire industrial chain. And product innovation, provide high-performance Klüber lubricants, meet the needs of the entire textile industry chain, achieve energy saving and emission reduction, and promote the sustainable development of the textile and garment industry.

1. In-depth research to clarify the lubrication problems in the textile and garment industry

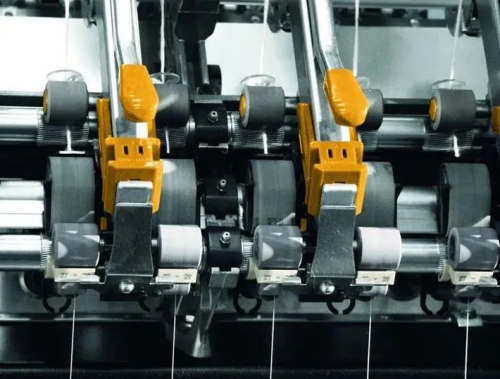

In order to provide effective solutions to lubrication problems, Klüber first conducted a survey on the textile and garment industry and found four pain points in the lubrication of spinning equipment, namely mechanical waves, oily yarns, non-wear resistance, and short lubrication cycles. In response to the above problems, technical research and product development were strengthened. After repeated tests and verifications, a special high-pressure resistant long-term grease was introduced to effectively reduce the mechanical waves brought by the top roller bearings, and at the same time avoid the appearance of "greasy yarn", so that the bearings can be lubricated more in place. It is understood that the lubrication cycle of this Klüber lubricant is as long as 5 years, and it has been selected as the designated lubrication brand by many international spinning equipment manufacturers.

2. Strengthen research and development and launch a "one moist, one clean" solution

Klüber believes that different spinning and garment equipment requires different lubrication solutions. To this end, we have increased the research and development of science and technology, and brought customers different experience with technology and innovation. For example, according to the technical characteristics and lubrication requirements of seamless underwear machine production, the solution idea of "one moist and one clean" is proposed, which effectively solves the problem of "black oil needles" in the production of seamless underwear, which not only improves the quality of underwear production, but also improves the production quality of underwear. It also reduces the operating temperature of the equipment, thereby reducing energy consumption.

3. Recycling helps textile and garment enterprises reduce costs and increase efficiency

Kluber believes that the core of sustainable development is to promote the recycling of resources while reducing pollution. They apply this philosophy to the development of lubricants. For example, it launched a new type of sustainable packaging oil drum. The lining weight of the oil drum is only 0.5 kg. Compared with the past, the weight of hazardous waste has been reduced by 97%. In addition, the new type of oil barrel is not only low in cost, but also reduces the residual amount of lubricant in the oil barrel. According to estimates, the emergence of this new type of oil barrel can help customers in the textile and garment industry save 2 million costs every year.

Kluber knows that strengthening sustainable development not only has economic value, but also has social value, and it is the focus of attention of the whole society. In the next step, Klüber will continue to leverage its industry and technological advantages, focus on the harmony between products and the environment, and ecological sustainability, and launch a series of environmentally friendly, energy-saving and efficient Klüber lubricants and solutions to meet the development needs of various industries.